Supplying the extreme temperatures needed for industrial processes – like cement, metallic and petrochemical manufacturing – accounts for spherical a fifth of full world vitality demand. Most of this vitality is generated by burning fossil fuels, releasing the equal of billions of tonnes of carbon dioxide into the ambiance yearly – roughly one third of humanity’s greenhouse gasoline emissions.

As such, discovering different methods to generate industrial course of heat is necessary as a result of the world makes an try to cut emissions and limit the worst outcomes of native climate change. Whereas hydrogen is often touted as a sustainable substitute for fossil fuels, in plenty of situations, the most effective technique could very effectively be to utilize utilized sciences that convert electrical power instantly into course of heat.

Matthias Rehfeldt, an skilled on industrial vitality demand on the Fraunhofer Institute for Strategies and Innovation Evaluation in Karlsruhe, Germany, explains that ‘there’s a big potential for direct electrification’ of many industrial processes. A present report commissioned by the clear vitality thinktank Agora Commerce and co-authored by Rehfeldt finds that 62% of economic course of heat inside the EU would possibly, in thought, be outfitted by direct electrification using utilized sciences which could be already accessible in the marketplace. This decide rises to 90% when factoring in utilized sciences which could be anticipated to attain market readiness inside the following decade.

As decarbonisation efforts progress, it is most likely {that a} combination of utilized sciences could be required to accommodate the actual needs of varied industries. As an illustration, metallic or ammonia producers working at temperatures properly in additional of 1000°C would possibly need to undertake utterly completely different approaches to distilleries or paper mills working inside the 100–200°C range. Nevertheless promisingly, a variety of utilized sciences could be discovered that appear ready to satisfy these vastly utterly completely different needs.

Lower temperature functions

Rehfeldt elements to heat pumps and electrical boilers as market-ready utilized sciences which could be already able to current heat for lower temperature processes. ‘The low temperature area could be very attention-grabbing, because of electrode boilers and heat pumps could be discovered,’ he says. ‘There are some challenges relating to upscaling … nevertheless it’s undoubtedly attainable already to do this. And heat pumps, in any case, ship a extreme effectivity profit as compared with commonplace fossil manufacturing and that makes them very attractive.’

Heat pump know-how has been spherical given that mid-1800s and transfers heat using the an identical concepts as a fridge, by rising and compressing a refrigerant gasoline. These strategies can recycle waste heat, or provide heat from the air, sea or ground and lift it to bigger temperatures. Because of heat pumps switch heat considerably than producing it, they will current lots bigger portions of heat output than they eat relating to electrical power enter – offering a big effectivity profit over completely different utilized sciences. Industrial objects can normally current pressurised steam at temperatures inside the 100–300°C range.

MAN Energy Choices is a primary producer of economic heat pumps that for a few years has outfitted strategies that get effectively waste heat from processes like propane dehydrogenation and fluid catalytic cracking at most important chemical refineries. Thomas Staude, who leads on industrial heat pump product sales at MAN, explains that in current occasions the temperatures, pressures and power output that the know-how can present has dramatically elevated. ‘Our portfolio of compressors is referenced as a lot as over 65MW electrical per casing – so for giant vegetation, enormous steam manufacturing requirements, you probably can merely go as a lot as 120–150MW thermal objects,’ he says.

‘The compressor is not the bottleneck anymore for heat pumps as a result of it was before now,’ offers Staude. ‘And neither is the temperature which you’ll be able to produce with one in every of these know-how … So the restrictions now are literally the coping with of these enormous heat exchangers, how one can mix it, logistics – nevertheless not the core gear know-how or the center of the heat pump itself.’

An increasing number of, the company has been supplying purpose-built heat pumps which will operate the first provide in fact of heat for industrial-scale operations. One occasion is a 5MW heat pump used to produce pressurised steam for Absolut Vodka’s ‘carbon neutral’ distillery in Åhus, Sweden. Sometimes, utilizing heat pumps in these initiatives is deliberate from the outset. Nonetheless, Staude says that the ‘subsequent drawback’ is to retrofit the strategies into present vegetation.

Whereas placing in heat pumps at pre-existing facilities is technically superior, Staude notes that MAN has effectively achieved a feasibility analysis on integrating new heat pumps into the steam neighborhood at BASF’s chemical refinery superior in Ludwigshafen, Germany. This is ready to doubtlessly present as a lot as 150 tonnes of steam per hour, reducing carbon dioxide emissions from the situation by as lots as 390,000 tonnes per yr. Nonetheless, Staude says that mission appears to be on keep whereas BASF adjusts to the monetary challenges which have impacted Europe’s chemical substances enterprise over the past two years.

In all places the place you probably can’t attain with a heat pump – because you need bigger temperature – then you definitely definately would go for electrode boilers

One different retrofit mission that is liable to be achieved inside the nearer time interval entails a dairy producer in New Zealand. ‘They really want to remove their coal boilers and want to current the strategy steam with a heat pump, so all indicators are pretty optimistic there,’ says Staude. ‘After which we’ve now a very, very attention-grabbing mission on the east coast of the US the place we’re retrofitting a heat pump into an outdated coal power plant to produce steam for the district heating grid of Boston.’

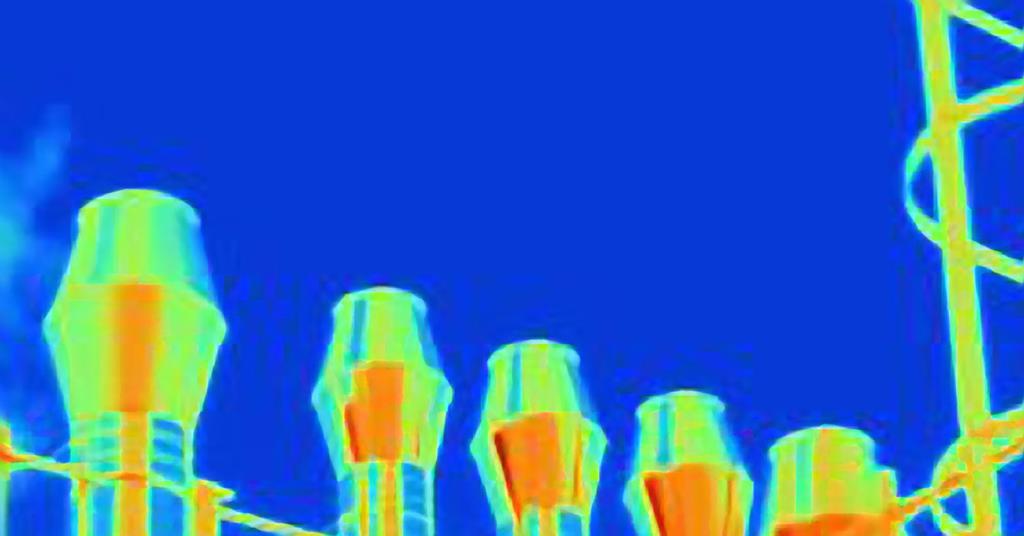

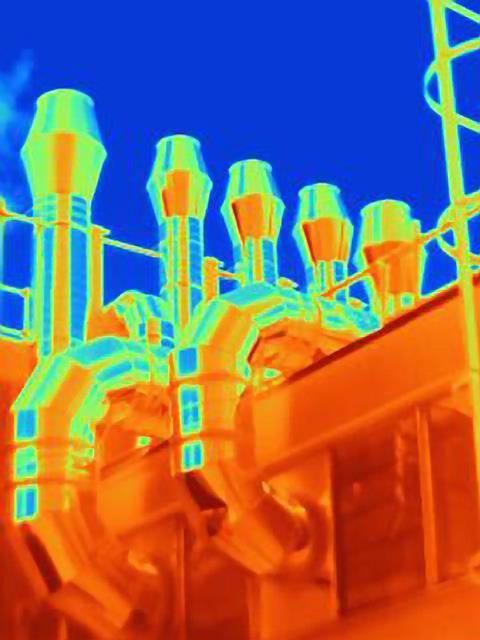

As one different well-established know-how, electrical boilers moreover current an selection for processes engaged on the lower end of the temperature scale. These can current superheated steam as a lot as 500°C and can be found two sorts: resistance boilers that heat water by means of a heating part, or electrode boilers the place current is utilized instantly by way of the water itself.

Rehfeldt notes that electrode boilers are the additional acceptable selection for bigger functionality industrial strategies. ‘We talked with one producer and the identical outdated shift from electrical to electrode boilers is at spherical 10MW – and so forth industrial scale, we’re talking about electrode boilers, primarily,’ he says. Nonetheless, boilers don’t have the effectivity profit of heat pumps – all the vitality to heat the water needs to come back again from {the electrical} power outfitted. ‘So I’d say, everywhere the place you probably can’t attain with a heat pump – because you need bigger temperature or the temperature elevate is simply too extreme – then you definitely definately would go for electrode boilers.’

Remaining yr, UPM launched that it’d arrange eight electrode boilers made by Norwegian producer Parat Halvorsen all through its paper mills in Germany and Finland. Electrode boilers put in on the agency’s Tervasaari web site moreover present heat for the native district heating neighborhood, together with the mill itself. In response to UPM, the boilers put in at its Finnish web sites will cut back spherical 50,000 tonnes of CO2 emissions yearly by reducing the need for pure gasoline.

Getting hotter

For the next range of temperatures from the low an entire lot as a lot as spherical 1000°C, completely different choices are required. For these processes, Rehfeldt elements to electrical resistance heaters as a number of the viable utilized sciences. These strategies make use of heating parts that each instantly or in a roundabout way change vitality to a cloth that should be heated.

Earlier this yr, a pilot demonstration that makes use of every strategies began operation at BASF’s Ludwigshafen refinery. These electrical crackers convert prolonged chain hydrocarbons into additional useful smaller molecules, producing spherical 4 tons of product per hour. BASF says that, when run on 100% renewable electrical power, the pilot crackers would possibly cut back spherical 90% of the CO2 emissions linked to the cracking course of when as compared with present cracker designs, which launch as a lot as two tons of carbon dioxide per ton of ethylene produced.

Resistance heating may additionally be combined with heat storage strategies, the place thermal vitality is saved in a cloth like a molten salt, sand or bricks. This vitality can then be launched on demand to produce scorching air or steam that may be utilized to drive industrial processes. These strategies may additionally assist to stability fluctuations in heat demand and electrical power present.

Rondo Energy is taken into account one in every of a variety of companies pioneering industrial-scale use of this know-how. Its container-sized refractory-brick-based heat batteries can current scorching air or steam heated previous 1000°C. The company claims that its objects retailer vitality with an absence of decrease than 1% per day.

‘The commercial fashions that we assemble are 100 and 300MWh and there’s a much bigger one as properly, that’s nonetheless being specified. A 300MWh heat battery delivers 20MW of regular heat, so it’s regarding the equal of an 85 million BTU an hour boiler,’ says John O’Donnell, Rondo’s founder and chief innovation officer.

‘It’s scorching enough to drive cement calcination – we’re setting up a mission correct now at a cement plant in Thailand – and to drive all the temperatures utilized in a petrochemical course of from ethylene cracking down by way of utility steam,’ he offers.

Remaining March, a 2MWh Rondo unit put in at a bioethanol facility in California grew to grow to be the first electrical thermal vitality storage system to enter industrial operation inside the US. The company has moreover reached agreements to place in objects at Diageo distilleries in Kentucky and Illinois which could be estimated to eliminate spherical 17,000 tons of greenhouse gasoline emissions yearly. That partnership is supported with a $75 million grant from the US Division of Energy that was awarded to help Diageo electrify its manufacturing web sites, with the aim of setting up them carbon neutral inside the following 4 years. The grant was part of a wider $6 billion effort launched by the US authorities in March to help 33 decarbonisation initiatives all through energy-intensive industries, which US vitality secretary Jennifer Granholm described as ‘a very powerful funding in industrial decarbonisation inside the historic previous of the US’.

One different mission receiving as a lot as $375 million from this funding pot is a model new chemical recycling facility for repurposing plastic waste being inbuilt Texas by the Eastman Chemical Agency. This facility will use onsite photo voltaic power along with Rondo’s heat batteries to decarbonise its course of heating. The mission is anticipated to produce virgin-quality polyethylene terephthalate (PET) with a 70% lower carbon depth than fossil virgin PET. Eastman says that PepsiCo has already signed a contract to utilize provides produced on the power to create sustainable packaging.

‘We’re at this tipping stage the place intermittent renewable electrical power delivered as regular steam or extreme temperature heat from a Rondo unit is turning into instantly aggressive with coal,’ says O’Donnell. ‘And over the next couple of years … as a result of the know-how deploys, there are areas the place the industries are setting up a variety of new infrastructure that could be worth environment friendly and clear, and by no means be “regret infrastructure” – not be stuff that as rapidly as we’re setting up it, we’re trying to find out the best way to decommission or change it.’

We’re at this tipping stage the place intermittent renewable electrical power, delivered as regular steam, is turning into aggressive with coal

Rondo has moreover simply currently confirmed varied initiatives in Europe, along with a 100MWh system at Covestro’s polymer plant in Brunsbüttel, Germany. The heat battery will present 10% of the steam required on the web site, saving as a lot as 13,000 tons of carbon dioxide emissions yearly. One different partnership will see Rondo work with Saudi Aramco to deploy heat batteries as a lot as a scale of 1GWh. O’Donnell notes that the company is working to assemble experience with utterly completely different electrical power networks along with improvement and finance frameworks in as many different territories as attainable, in an effort to clear the long term deployment of its know-how at scale. The company has set itself the formidable goal of chopping 1% of the world’s full carbon dioxide emissions over the next decade, and a staggering 15% inside 15 years.

‘Everyone knows the world urgently needs this decarbonisation transition as fast as attainable, and we don’t get to creating contributions at scale with out proving ourselves in these geographies,’ he says. ‘We have initiatives the place the ambient temperature is –60°C and initiatives the place ambient peak temperature is +60°C as part of the design basis. We have initiatives making nearly every commodity all through paper, chemical substances, gasoline refining, meals, cement – so we’re establishing the inspiration now.’

Hitting 3000°C?!

For however bigger temperature functions like steelmaking, Rehfeldt and Agora stage to induction heating and electrical arc furnaces as present utilized sciences which could be already being utilized in enterprise.

Induction furnaces, which heat metallic by way of a rapidly reversing magnetic topic, are already used for in some smaller and speciality metallic vegetation. Crucial examples have been put in spherical 10 years prior to now by ABP Induction at a stainless-steel facility in Taiyuan, China. These 42MW furnaces can heat as a lot as 65 tonnes of metallic to spherical 3000°C.

Electrical arc furnaces can heat supplies to temperatures as a lot as 1800°C by exposing it to a plasma arc and are increasingly more utilized in scrap-based steelmaking. These are additional acceptable for greater scale functions, with furnaces providing power of as a lot as 200MW. The world’s largest electrical arc furnace is put in at Tokyo Metallic’s plant in Tahara, Japan, and would possibly keep 420 tonnes of cloth.

Newest analysis by World Energy Monitor (GEM), which tracks the operations of the 1200 largest iron- and steelmaking facilities throughout the planet, reveals that 93% of deliberate new steelmaking functionality launched closing yr will make use {of electrical} arc furnaces. This represents a dramatic shift – of the model new steelmaking functionality launched in 2020, merely 36% was to be primarily based totally on electrical furnaces.

Nonetheless, the GEM report notes that decrease than 14% of the deliberate electrical arc furnaces have moved into the event half – meaning that almost half of the initiatives which could be at current beneath improvement are nonetheless primarily based totally on coal-burning blast furnaces.

‘The progress is promising for a inexperienced metallic transition. Certainly not sooner than has this lots lower-emissions steelmaking been inside the pipeline,’ well-known GEM’s director for heavy enterprise, Caitlin Swalec. ‘On the same time, the buildout of coal-based functionality is concerning. What the enterprise needs now’s to make these clear enchancment plans a actuality, whereas backing away from coal-based developments.’

Overcoming limitations

Whatever the provision of utilized sciences which have the potential to slash enterprise’s emissions, limitations to their deployment keep. A serious concern surrounds worth. ‘Everytime you check out your full lifespan of an arrange that provides course of heat, the general worth of possession is about 80% dominated by the vitality costs – usually additional,’ notes Rehfeldt. ‘The [capital expenditure] is often low: maybe 10–15%, nevertheless that’s over your full lifetime – it’s nonetheless an issue to have an intensive [capital] funding because of you can have the capital on the market, you’ve got a extreme uncertainty, so it is necessary to weigh your risks. From the individual perspective of a corporation or manufacturing web site, that may nonetheless be a barrier, nevertheless making an attempt on the whole costs, it’s usually not and further the operational costs is the higher drawback.’

With vitality costs contributing such a extreme proportion of the general costs, Rehfeldt elements out that transitioning to decarbonised vitality sources brings a clear monetary drawback. Electrical power normally costs additional per unit of vitality than fossil heat sources. Even accounting for elevated effectivity of electrified processes, which will make it arduous to make an monetary or enterprise case out of switching. ‘That signifies that the economics in a roundabout way need to range,’ he says.

Everytime you electrify you substitute your thermal load that you simply simply beforehand outfitted with pure gasoline with electrical power, nevertheless you need utterly completely different infrastructure for that

Loads of mechanisms could possibly be exploited to make electric-powered processes aggressive with present fossil-based processes, Rehfeldt explains. These embody elevated carbon pricing to spice up the value of emissions-intensive manufacturing, and better subsidies for electricity-based manufacturing, along with lower grid costs. ‘There’s moreover a third aspect … this distinction can also be in a roundabout way lined by the market,’ offers Rehfeldt. ‘If clients are ready to pay additional for a inexperienced product, this [cost] distinction could very effectively be addressed by that.’

There are moreover technical challenges for decarbonising industrial heat. Clearly providing enough renewable electrical power to provide industrial processes which have been beforehand pushed by fossil fuels requires giant deployment of photograph voltaic, wind and completely different renewable power. Nevertheless whilst quickly as {the electrical} power is obtainable, there could possibly be limitations to bringing electricity-driven processes on-line.

‘Everytime you electrify you substitute your thermal load that you simply simply beforehand outfitted with pure gasoline with electrical power, nevertheless you need utterly completely different infrastructure for that. You’ll have the pure gasoline connection, nevertheless these are normally inside the area of double-digit megawatts – and some industrial web sites solely have 5–10MW electrical power connections, which they’re already using, and so should lengthen {the electrical} power grid connection. That’s one factor that takes an entire lot of time. I do know that for Germany, it could take 4, 5 years or longer to do this,’ says Rehfeldt. ‘And that signifies that your window of different for reinvestment is prolonged gone. If it is necessary to attend 4 years to spend cash in your core enterprise, then you definitely definately merely spend cash on the fossil arrange and by no means inside the electrical one, even while you would have had a enterprise case for it.’

In response to O’Donnell, one closing drawback surrounds consciousness of the utterly completely different potential choices to the difficulty of decarbonising industrial heat. ‘There are numerous organisations the place the chief authorities might ask the workers: “What’s our hydrogen approach?”,’ he says. Nevertheless whereas hydrogen might have a process in decarbonising certain specific processes, it is liable to be reasonably extra expensive and inefficient than direct electrification usually. ‘There aren’t that many organisations the place they’re asking: “What’s our electrical thermal vitality storage approach?” or additional broadly, in a know-how neutral strategy, “What’s our clear vitality approach? And what are the pathways?” So consciousness is admittedly nonetheless the first draw back,’ O’Donnell concludes.