Biochemist Charlie Bavington is on the hunt for someplace to put a wide range of seaweed. His agency, Oceanium, plans to take 2000 tonnes of farmed kelp per yr and swap it into nutraceuticals, components for meals and cosmetics, and additional furthermore. Nevertheless Bavington, who co-founded the company in 2018 and is now chief technical officer, says this new facility will solely be the demonstration plant. Lastly, he hopes to roll out crops with 10 events the aptitude. ‘We are going to then put a type of wherever on this planet there could also be ample kelp to feed a producing facility, and it will primarily produce the an identical suite of merchandise,’ he says.

Oceanium’s technique goes a manner within the route of realising the thought of a ‘seaweed biorefinery’ – a time interval utilized in Europe’s rising seaweed enterprise to clarify the transformation of seaweeds proper right into a cascade of assorted merchandise and chemical substances. It is primarily macroalgae’s reply to an oil refinery. Merchandise range from expensive complement powders and biodegradable packaging to environmentally nice animal feeds. The idea has captured the imaginations of scientists and entrepreneurs alike – along with funding our our bodies – for the potential benefits that farmed seaweed could provide the environment and coastal communities. Nevertheless can companies like Oceanium profit from what seaweed has to provide and do it sustainably, at scale?

Oceanium depends in Oban on the west coast Scotland, inside easy attain of seaweed farms – the place seaweed is seeded onto ropes stretched out inside the water, like rows of crops in a space. Nevertheless the agency works largely with greater producers, along with one inside the Faroe Islands that seeded 27km of line this yr. Each kilometre produces roughly 10 tonnes. In response to Bavington, Oceanium works primarily with sugar kelp, an unassuming brown seaweed with crinkly fronds. ‘That’s what’s on the market – it’s nearly all of the cultivation,’ he says.

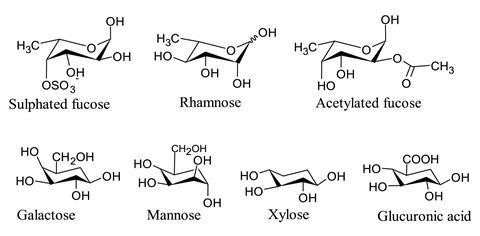

Oceanium doesn’t buy wild harvested kelp, because of it’s ‘environmentally damaging at big scale’, nonetheless that’s at current how most seaweed outside of Asia is produced. Nonetheless, on the ultimate rely, 13 European nations along with Norway, France, Spain and Portugal had industrial seaweed farms. One amongst sugar kelp’s elementary sights is its huge distribution – it’s current in British waters along with all through the Arctic, Atlantic and Pacific oceans. All brown seaweeds, though, and the purple and inexperienced ones, are jam-packed with polysaccharides. These prolonged chains of sugar molecules are key targets for biorefiners who have to extract and purify them or transform them into totally different useful chemical substances.

Algal improve

Seaweeds’ sugary objects are no secret, the truth is. Sugar kelp obtained its establish from the powdery white substance – mannitol, a sugar alcohol and sweetener – that crystallises on its fronds when it dries. And, for a few years, the meals enterprise has used seaweed alginates, agars and carrageenans (all polysaccharide-based) as hydrocolloids for thickening, stabilising and gelling brokers. Nevertheless the current hype spherical seaweeds centres on their untapped potential, which extends from sugars to proteins and pigments.

The World Monetary establishment predicts that by 2030 {the marketplace} for seaweed-derived nutraceuticals alone will be worth $3.9 billion (£3 billion). The macroalgal improve should see seaweed aquaculture proliferating in Europe and previous. Australia, for example, is appropriate now ploughing considerable efforts into harnessing halogenated compounds in a purple seaweed referred to as Asparagopsis to make cattle feed parts that cut back ranges of methane (a potent greenhouse gasoline) in cows’ burps. In May, Mars launched it was partnering with a Tasmanian seaweed agency and New Zealand dairy producers to examine whether or not or not Asparagopsis dietary dietary supplements can cut back the affect of its chocolate on the native climate.

In a brilliant world, seaweed farmers’ produce wouldn’t merely be purchased to cattle feed producers. Under the biorefinery thought, it may very well be bought by a refiner like Oceanium and used to make various completely totally different merchandise. Although according to Mike Allen, a marine biotechnologist on the School of Exeter, UK, no one is doing this at scale correct now, because of the enterprise stays to be too fragmentary. ‘There’s no large pipeline you may put the entire seaweed biomass into so that it comes out as completely totally different merchandise,’ he says, noting that supply factors are moreover stopping scale-up. ‘So in the mean time, we’re caught at small-scale, artisan, cottage enterprise biorefinery.’

Nonetheless, it’s not practically what producers may make using seaweed. Schemes could shortly exist to award credit score for ‘blue carbon’ storage in farmed seaweeds or so that funds may very well be made for using them to scrub up marine waters – seaweeds can soak up polluting nutritional vitamins like nitrates and phosphates current in agricultural run-off. The seaweed enterprise could faucet into this mixture of upstream service price and downstream product price, Allen says. ‘So everytime you focus on a refinery, it’s maybe that it’s a product refinery and a service refinery.’

Oceanium locations a wide range of emphasis on the service values, although it doesn’t monetise them. Alongside water purification, its promotional provides cite environmental benefits equal to habitats for marine species, a functionality to take up carbon dioxide and the reality that you just don’t should fell a forest to start a seaweed farm. Bavington, though is cautious to not overpromise on carbon storage, noting that ‘the merchandise we make are consumed or biodegraded, so it’s spherical’.

Bio-massive potential

Inside Europe, there in the meanwhile are total networks of scientists plugged into the potential of seaweeds via EU funding programmes. One is chemist Anne Meyer on the Technical School of Denmark (DTU) near Copenhagen, whose fascination with macroalgae grew from an curiosity in numerous varieties of biomass for making biofuels. As she explains, her work focuses on using enzymes for the ‘upgrading, conversion, degradation or transformation’ of pure substances – and she or he’d already sifted via many plant-based decisions, which had been stiff and troublesome to interrupt up on account of their extreme lignin content material materials.

Seaweed, which is floppy and nearly devoid of lignin, appeared the correct numerous. Since turning into a member of an EU-funded seaweed problem, nonetheless, Meyer’s evaluation has broadened out to embody a wider array of potential merchandise accessible via biorefining. ‘It’s a superb thrilling space, because of it has all you want,’ she says. ‘It has the sustainability and it has the enlargement potential.’ Every DTU and Oceanium are companions inside the EU-funded consortium Seamark, which objectives to scale up seaweed cultivation and processing all through 12 progressive merchandise, from pig feed to prescribed drugs.

The suite of potential merchandise for a worthwhile seaweed biorefinery tends to be envisioned as a pyramid of low-, medium- and high-value merchandise, with the low-value bulk (along with biofuels) on the bottom, medium-value merchandise along with meals and cosmetics components inside the heart, and small volumes of high-value merchandise like remedy on the excessive. Hydrocolloids match someplace inside the heart, though Oceanium is avoiding competing with this well-established market, along with biofuels, which Bavington says ‘aren’t economically viable from seaweeds’. Seamark’s plans don’t embrace biofuels each.

Hydrothermal liquefaction is like geology in a tin

As Allen explains, making low-cost fuels out of seaweed requires a course of that is associated in scale to the cracking of crude oil inside the petrochemical enterprise. ‘You need an oil refinery – that type of infrastructure, because of you could’t do that on a small scale,’ he says. ‘There’s a trigger why oil refineries are large and it’s because of they need economies of scale.’

Technically, though, turning the hydrocarbon skeletons in seaweed into oil isn’t that powerful and if economics weren’t an issue, this ‘bio-oil’ could, theoretically, substitute crude oil as a provide for every liquid fuels and totally different chemical substances. Earlier this yr, Allen revealed a paper on a hydrothermal liquefaction (HTL) course of that he used to make oil out of beached brown Sargassum seaweeds, which might be the an identical genus as sugar kelp.

Giant blooms of these seaweeds – fed by nutrient run-off from farming – clog up a complete 8000km stretch of the Atlantic Ocean from West Africa to the Gulf of Mexico, smothering marine life and kicking up a stink on Caribbean seashores, the place they rot and emit hydrogen sulfide. Allen and Matthew Pearce, from PureFire Labs in Cambridge, shipped a number of of this nuisance seaweed once more to the UK and subjected it to HTL, which Allen likens to ‘geology in a tin’: high-pressure, high-temperature processes resembling individuals who create oil deposits on geological timescales, nonetheless condensed into a few hours or days in a reactor. HTL may very well be achieved moist, a bonus in cooler nations identical to the UK, the place sun-drying is often out of the question. Nevertheless the course of nonetheless consumes far an extreme quantity of energy, Allen says, for it to be economical – till, perhaps, the availability seaweeds are seen to have some additional service price.

Sweet retailer

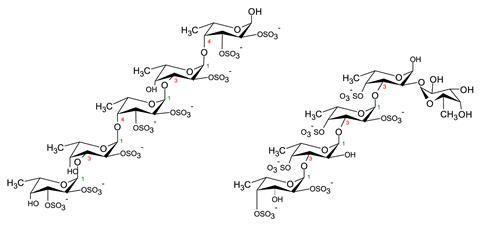

Whereas Oceanium isn’t dipping its toe into biofuels, it already produces and sells high-value ‘bioactives’ (for meals and cosmetics), along with a beta-glucan and sulfated seaweed polysaccharides referred to as fucoidans – extensively studied for his or her anti-inflammatory, antioxidant, anti-viral and anti-cancer actions. The middle of Oceanium’s biorefinery pyramid is at current occupied by medium-value fibres purchased as meals components and biodegradable printing inks. Nevertheless the agency’s portfolio seems to be like set to develop, as moreover it’s exploring low-value packaging and totally different provides functions for these fibres, along with the best way it may use sugar kelp’s minerals, proteins, and the sweet, powdery mannitol that impressed its establish. Whereas mannitol may very well be purchased as a meals sweetener, it might also act as a platform chemical for accessing totally different buildings.

Bavington refers to Oceanium’s processing as ‘fairly simple cascade biorefinery’, involving delicate, water-based extraction, separating the soluble and insoluble components, after which fractionating the soluble ones to make the desired merchandise. The chemistry, he says, is already pretty inexperienced, nonetheless your entire course of may probably be greener if additional of what’s at current wasted was used. ‘The stuff that’s in our waste stream in the mean time should not be considerably environmentally harmful, nonetheless we’ve got to valorise that,’ he says. ‘We’re an affect enterprise, and it merely helps the final affect and economics of the tactic if we’re capable of flip these into merchandise as properly.’

One technique to make the most of out of the seaweed that is fed into biorefinery processes, and maintain the chemistry inexperienced, is to drive these processes using seaweed-specific enzymes. These enzymes, Meyer says, are more likely to perform beneath gentler conditions than commonplace refining processes and should act like ‘molecular tweezers’ for teasing out chemical treasures. On this technique, extreme temperatures, acids and toxic solvents may very well be averted, and the milder processing means provides that will develop to be valuable extra downstream are saved from wreck. Nevertheless the place do such enzymes come from?

Typically enzymes for specializing in seaweed polysaccharides come from crops, nonetheless monitoring down these which will be notably well-suited to seaweeds can require additional legwork. ‘That is because of seaweeds have not been explored so properly,’ says Meyer. ‘And one of the best ways they’re constructed is completely totally different to crops, so we now need to seek for new enzymes.’ One fertile wanting flooring is inside the bugs that dwell and feed on seaweeds. As an example, by sequencing DNA and protein from a marine fungus found on decaying seaweeds, Meyer’s workforce tracked down new enzymes for degrading alginates.

Enzymes that think about alginates could help to launch fucoidans, like these Oceanium is producing as bioactives. This might sound counterintuitive provided that enzymes are alleged to be explicit, nevertheless it absolutely seems to work because of fucoidans are thought to be intertwined with alginates (and cellulose) in seaweed’s sugar-stacked cell partitions. When Meyer’s workforce examined a mixture of alginate- and cellulose-digesting enzymes with sugar kelp, they obtained fucoidan yields corresponding to those from harsher, chemical extractions, and better, better-preserved fucoidans. Within the meantime, they’ve simply recently unveiled the development of an enzyme from a marine bacterium that targets fucoidans immediately. Such fucoidanase enzymes had been comparatively unknown until simply recently.

Enzyme-based approaches are already in enchancment at Oceanium, with Bavington noting the number of ‘attention-grabbing modifying enzymes’ for fucoidans. Enzymes can also be used to tinker with beta-glucans to provide a numerous array of buildings, along with some shorter chain oligosaccharides which will even uncover pharma functions.

Refine to revive?

Thus far, refiners may have solely scratched the ground of what it is potential to make with seaweeds. Nonetheless, their exploitation does need cautious stewardship. Major shifts in how seaweed species are distributed all through the globe are underway on account of native climate change, which implies that whereas some areas, identical to the Caribbean, may look like beneath siege, others, like Australia, are seeing their seaweeds disappear. The dearth of so-called kelp ‘forests’ has penalties for fish and totally different species that dwell in them, and marine carbon retailers.

Georgina Picket, an Australian seaweed scientist who has spent the ultimate eight years engaged on restoration initiatives, is now at Flinders School in Adelaide, the place the federal authorities funds her evaluation on kelp aquaculture. Lots of her restoration work was based mostly totally on appropriating Norwegian methods developed for farming sugar kelp to aim to revive Australia’s dwindling underwater forests. Nevertheless she thinks aquaculture is now important to upscale restoration. ‘Because it’s, there’s no technique to revive on the dimensions that we’re at current shedding marine forests at with out aquaculture,’ she says. ‘So we would like that enterprise to draw on.’ She’s moreover optimistic that because of Australia’s seaweed enterprise is so youthful, there are nonetheless options to help the occasion of pointers that assure sustainable improvement, with fewer hostile impacts for the environment.

Throughout the UK, within the meantime, the small scale of farmed manufacturing stays certainly one of many essential boundaries to improvement of the seaweed enterprise. Seaweed manufacturing globally may have tripled inside the closing 20 years, nonetheless UK farmers face a difficult regulatory panorama, along with battle with fishers and residents in some coastal areas the place farms are proposed.

Allen’s decision is to broaden into offshore areas, using dynamic, drifting cultivation packages equipped with automated monitoring. These are methods he’s rising with software program program and robotics engineers as co-founder of Seaweed Period, a company centered on decarbonisation – for now, nonetheless with large plans for the long term. ‘It’s about rising the robotic infrastructure to cultivate seaweeds so efficiently and successfully – and cheaply – that every a type of merchandise we’ve talked about may very well be nailed,’ he says. ‘You probably can [then] put these merchandise in pipelines which will be at current using fossil fuels. Nevertheless to get there it’s essential to be taught to do all these totally different points and that imaginative and prescient is so far-off.’

Allen’s hi-tech packages would modernise an enterprise that he says relies upon too carefully on methods drawn from typical crop farming. Bavington, though, is additional optimistic, suggesting that advances in seaweed farming know-how and breeding methods are set to ship ‘a big uplift in yield and low cost in worth’ inside the subsequent couple of a very long time – nonetheless solely as demand dictates. In the meanwhile, he says, farmers are prepared for the demand that companies like Oceanium can create. ‘It’s at a closing date for the enterprise now the place, as long as we and totally different biorefiners are worthwhile, and we make these merchandise that the market wants and get that market traction, then your entire factor will develop pretty quickly.’

As for his demo plant, location recognizing has been troublesome, nonetheless his zero-waste ambitions suggest he’s not looking for to start from scratch. ‘If anyone is conscious of of an empty manufacturing facility we’re capable of repurpose, we’d like to not assemble a model new one,’ he laughs.

Hayley Bennett is a science creator primarily based in Bristol, UK