Enterprise’s reliance on petrochemicals is probably going one of many main reason why electrochemical synthesis was on no account completely explored says Tobias Gärtner, chief govt at ESy-Labs, a start-up positioned in Regensburg, Germany, that specialises in electrosynthesis know-how. Modern industrial pure chemistry has developed to successfully exploit fossil fuel-based hydrocarbon feedstocks and swap them into chemical merchandise using classical pure chemistry, from the nylon fibres in our clothes to the factitious flavours in our meals.

The carbon toll of these industries – the chemical sector being the third largest industrial emitter of carbon dioxide – and a legacy of polluting waste is principal chemists to hunt for greener processes. And so they’re turning to electrosynthesis: using {an electrical} current to facilitate chemical reactions instead of chemical redox brokers. ‘Electrochemistry was a definite section [method] nevertheless an rising variety of it’s coming out of the world of curiosity and being recognised as an precise synthetic method,’ says Gärtner. Nonetheless whereas publications and funding in electrosynthesis have been on the rise throughout the ultimate decade, tutorial tendencies don’t on a regular basis effectively make their methodology to commerce.

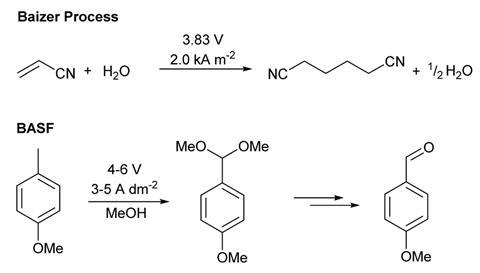

Electrosynthesis has on no account been absent from the chemical commerce. Curiosity tended to rise in situations when crude oil prices rose or electrical vitality prices fell, elements out one among ESy-Labs’ co-founders, Siegfried Waldvogel from Johannes Gutenberg Faculty Mainz in Germany who has been working in electrosynthesis for 30 years. One in all many earliest examples from 1849 is the Kolbe response, the electrosynthetic radical coupling of two carboxylic acids. There was moreover an upsurge in curiosity throughout the Sixties with the Baizer course of developed by Monsanto. This cathodic low cost of acrylonitrile to adiponitrile is used to yearly produce throughout the differ of 100,000 tonnes of the polyamide nylon-6,6, a superior sort of nylon, produced from hexamethylenediamine and adipic acid (hexanedioic acid).

The latest resurgence comes with the issue to decarbonise the chemical commerce and the hope that cheaper renewable electrical vitality might be utilized to fuel these reactions. That’s really the case for biotechnology agency Vertex Prescribed drugs, who consider rational design approaches to drug discovery. ‘The flexibleness to place off reagents and easily use electrical vitality, significantly if it comes from a inexperienced provide, is definitely a consideration,’ says Vertex principal scientist Robert Inexperienced.

Looking out for shortcuts

Agrochemicals specialist Syngenta started having a look at electrosynthesis spherical 2017, after Waldvogel gave a chat at their evaluation labs in Switzerland. Chris Scarborough, who was then working in course of chemistry, says he was notably struck by the tendency in commerce to steer clear of direct oxidation reactions that are typically dangerous, and instead use workarounds involving far more steps along with nitrations, reductions or diazotisations. Electrosynthesis may provide additional direct routes, plus a simple safety lever. ‘If there was a problem, chopping {{the electrical}} present may also stop a runaway response or one factor dangerous going down,’ says Scarborough.

The other safety profit is the eradicating of toxic reagents presently utilized in lots of normal pure syntheses, along with noble metallic catalysts. ‘[This is important] significantly throughout the pharmaceutical commerce the place you will need to be sure that there is not a contamination,’ says Waldvogel. Electrosynthesis moreover ensures a lot much less waste. ‘[For example,] must you’re not using sodium borohydride as a decreasing agent and producing boron oxides as byproducts, it’s doubtlessly a so much cleaner synthetic technique,’ says David Hodgson, a specialist in industrial electrochemisty and chief know-how officer at superior provides producers Technical Fibre Merchandise.

Worth at scale is the underside line for a lot of commerce reactions, although that isn’t on a regular basis the case for medicinal chemists, because of the value of an brisk pharmaceutical ingredient is so extreme as compared with bulk and even excellent chemical, says Pierre-Georges Echeverria, R&D director at US sustainable specialty chemical agency Pennakem. ‘For medicinal chemists [they are looking for] fast cuts throughout the synthesis,’ he offers. ‘When the chemistry is straightforward, even when the yield is not that good, they don’t care: they’ve the molecule and that’s good.’

The hope will also be that electrosynthesis might current entry to new chemistries via the free radical intermediate species that are produced in an electrolysis cell. ‘The chemical response concept behind [electrosynthesis] is often totally utterly completely different as compared with normal chemical reactions,’ explains Gärtner. ‘There are an excessive amount of examples of establishing attention-grabbing heterocycles that had been pretty frankly a ache to make, which you possibly can [make more easily] and pharma and agrochemicals are stuffed stuffed with attention-grabbing heterocycles.’

Dimension points

The difficulty for commerce is on a regular basis scaling up the reactions developed in tutorial labs. Echeverria says he started experimenting with electrosynthetic oxidations of secondary alcohols in 2016 at Minakem, a sister agency focused on making energetic pharmaceutical components. He was attempting to cut back the oxidant waste generated. ‘It actually works pretty successfully, [but] in the intervening time we gave up on this matter, because of lack of scale up choices.’ A shortage of standardised gear for scale stays to be a limitation going via commerce, he says.

The group at Syngenta has moreover grappled with scale, and notably shifting between the utterly completely different scales they need for fast early exploration after which shifting to producing greater portions, all ideally working beneath the equivalent circumstances. Course of study chemist Matthias Lehmann says they now have two packages on the 100mg scale to provide the possibility ‘to ship an answer as to if a metamorphosis is possible or not’. Nonetheless they found that although enterprise gear existed for very large scale manufacturing there was nothing to evaluate industrially associated scale-up circumstances on the gram scale, so that they designed their very personal gear, which they nonetheless use within the current day.

When scaling up, ‘typically all these processes change to flow into’, says Inexperienced. Motion chemistry permits reactions to run in a gentle stream reasonably than in batches and is a well-established methodology for large scale manufacturing. At scale, working in flow into is crucial because of in batch the scale of the required electrode ground would moreover have to be scaled up, making the whole cell unmanageably large.

Can we do an electrosynthetic response proper right here, and might this save steps or waste?

The problems of mass transport of reactants at greater scales is even increased for electrosynthesis than for traditional scale ups. ‘You need to transport starting provides to your two electrodes and take away the product out of your electrodes and this must be matched with the response kinetics,’ explains Syngenta evaluation chemistry group chief Andrei Iosub. Syngenta have experimented with together with mixers to their electrochemical flow into cell to increase mass swap prices.

The number of corporations who’re introducing new electrosyntheses is not clear says chemist Kevin Lam from the Faculty of Greenwich throughout the UK. He has labored with every GSK and AstraZeneca, nevertheless he says corporations normally aren’t on a regular basis open about their new strategies so it’s troublesome to know. Some corporations on no account stopped electrosyntheses; Lam these days noticed German chemical agency BASF have long-standing patents on electrosyntheses which have solely merely been printed throughout the tutorial literature.

Syngenta are to this point solely working at a small scale. ‘Every time now now we have an attention-grabbing oxidative transformation, we predict “OK, can we do an electrosynthetic response proper right here, and might this save steps or waste?”’ says Iosub. They’re moreover contemplating fastidiously about how a couple of of the traditional ingrained workarounds to steer clear of direct oxidations might current alternate options for easier direct electrosynthesis. ‘We found that there are a lot of thrilling alternate options for electrochemistry in our environment,’ says Scarborough. The group are constructive it’s solely a matter of time sooner than one such response is scaled up for manufacturing.

Vertex are moreover throughout the early ranges. ‘We’ve developed some inside capabilities to have the power to quickly optimise and show utterly completely different reactions’ nevertheless, says Inexperienced, ‘we’re nonetheless assessing the literature, understanding the place the easiest impacts is perhaps made.’

Electrode design

Since his first foray in electrosynthesis, Echeverria and colleagues partnered with principal tutorial electrosynthetic chemist, Phil Baran from the Scripps Evaluation Institute in California, US, to see if they could develop greener and cheaper electrosyntheses. They developed a furan oxidation to synthesise 2,5-dimethoxydihydrofuran (DMDHF), used to make all types of invaluable chemical substances paying homage to pyridazine utilized in agrochemicals and flavour enhancer maltol. The furan starting supplies received right here from the bio-based sugar dehydration product furfural (C₄H₃OCHO) and the pilot was able to produce a kilogram per week, attending to a gift effectivity of 88% (which implies 88% of electrons delivered contributed to the required response). Echeverria says this course of would compete with DMDHF produced conventionally in China and will probably be ‘a sport changer’.

The Minakem group moreover labored with Baran to develop a carbonyl desaturation response which may proceed with out the huge portions of pricy palladium catalyst used inside the usual synthesis. The kind of response offers a carbon–carbon double bond subsequent to a carbonyl group to open up downstream reactivity. They received right here up with a simple course of, scalable to 100g.

The electrode supplies and design is probably going one of many important components in electrosyntheses. ‘Do you have to don’t get the proper electrode supplies, the proper current density and the proper engineering, you probably can end up making a extremely utterly completely different combination of merchandise than you’d want, so that impacts selectivity and it impacts yield,’ says Hodgson. ‘Points like [electrode] porosity goes to be important.’ His agency are having a look on the sort of superior provides which can improve electrode effectivity.

It’s 200% effectivity if every electrodes are productive

Optimising the weather contributing to worthwhile electrosyntheses, notably the choice of electrode, is often trial and error. ‘If you’ve received an entire lot of experience, you possibly can have a kind of intuition, in spite of everything, nevertheless the difficulty is, even in my case, I was constructive that in [a particular] response, this electrode ought to hold out considerably higher nevertheless the experimentation turned out differently,’ says Waldvogel. His start-up ESy-Labs, primarily based in 2018, is hoping to differ that.

‘Should you change from 25 to 35°C, you see a dependence on the response, nevertheless switching from copper to carbon and there is not any dependence,’ explains Gärtner. ESy Labs is using AI and completely different statistical methods to raised optimise processes. They’re ending up extreme throughput electrosyntheses – from 40–80 reactions in parallel – to create ample data elements to teach an AI system to ascertain the easiest electrode supplies, solvent or electrolyte for any given response and hope this may aide in designing new processes.

Lam says that the holy grail for industrial electrosynthesis might be a paired electrosynthesis the place a useful product is produced at every the anode and cathode. ‘That’s really unbelievable – it’s 200% effectivity because of every electrodes are productive.’ An prolonged established occasion is German chemical producer BASFs manufacturing of the aromatic aldehyde lysmeral (butylphenyl methylpropional) which provides an artificial lily of the valley scent, as quickly as produced on the ten,000 ton per 12 months scale (it is now banned from cosmetics throughout the EU and UK because of its endocrine disrupting properties). The electrosynthesis produces an intermediate methoxy benzaldehyde on the anode which undergoes further reactions to type lysmeral. On the cathode a benzenedicarboxylic acid is decreased forming phthalide, a chemical used to offer fungicides. ‘It’s what I might ponder the slam dunk software program, in case you’ll discover one and scale up the electrochemistry,’ says Iosub

A hybrid technique

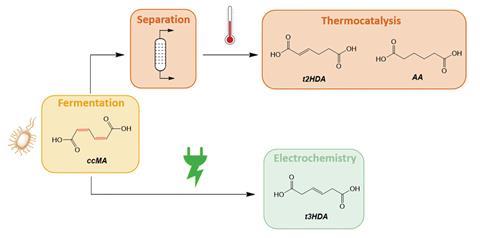

Jean-Philippe Tessonnier, a chemical and natural engineer at Iowa State Faculty throughout the US, is attempting one different technique: hybrid microbial electrosynthesis. This combines the power of biocatalysis and a few nice advantages of electrosynthesis, using biomass feedstocks. With low-cost renewable electrical vitality this begins to look economically attractive.

Tessonnier says that biosyntheses using micro organism or yeast is perhaps setting pleasant at some chemical conversions nevertheless not others – notably eradicating carbon–carbon double bonds. ‘Presumably biology ought to focus on what it does successfully, and let chemistry do the remaining,’ he explains. The tactic developed with colleagues on the Coronary heart for Biorenewable Chemical substances initially aimed to offer adipic acid – the nylon feedstock usually derived from petrochemicals by way of a variety of oxidation steps. Over 3 million tons of it are made yearly, producing the same quantity of nitrous oxide greenhouse gasoline.

Considerably than separating the phenol starting supplies produced throughout the fermentation broth from completely different impurities, Tessonnier decided to see what would happen if he merely caught in some electrodes. ‘Fermentation broths comprise an entire lot of salts, magnesium sulfate and completely different points, so this already seems like an electrolyte,’ he reasoned. In 2021, their first experiments, microbially reworked sugars or lignin monomers into the dicarboxylic acid cis,cis-muconic acid (C6H6O4), which that they had been then able to electrochemically hydrogenate to remove the double bond and type trans-3-hexenedioic acid at very extreme yields. Whereas not their meant product, moreover it’s a invaluable monomer because of it could be used to offer nylon 6,6 with connected purposeful groups to introduce novel properties.

Tessonier has now moreover printed a hybrid method to offer adipic acid, using supported palladium nanoparticles on carbon as a catalyst which facilitates electron swap and the following low cost to adipic acid on ground terrace web sites. Totally different groups are pursuing associated approaches along with a Kolbe electrosynthesis to couple medium chain fatty acids from fermented biowaste to offer hydrocarbon fuels.

Although electrosynthesis undoubtably has the potential to be greener, it may not on a regular basis be the easiest decision in accordance with Lam. {The electrical} vitality costs normally aren’t negligible: ‘At large scale, every single volt will eat extra cash, so that you need to have a extremely setting pleasant course of,’ and he says there’ll nonetheless be waste. ‘We have in order so as to add a substantial quantity of supporting electrolyte – not on a regular basis, nevertheless pretty typically for reactions, and it doesn’t contribute to one thing throughout the response.’

‘What I haven’t seen a whole lot of in electrochemistry however is principally superior molecules,’ concedes Inexperienced. ‘Large molecules which have gotten a variety of efficiency.’ By controlling the potential, you probably can ‘tune in’ the reactivity to a specific part of a molecule nevertheless ‘Primarily, you probably can solely tune in to the underside energy [reaction] – that’s on a regular basis going to go first,’ he says. It’s moreover troublesome to manage stereochemistry. For now it is largely restricted to producing the earlier establishing block molecules, nevertheless clever catalysts or electrode design might current further administration and Inexperienced hopes the evaluation neighborhood will provide you with choices. ‘As people apply it to additional superior molecules, we’ll see how far can you push it.’

Electrosynthesis is not magic

Inside the meantime, shifting electrosynthesis into commerce suffers from the equivalent points as a result of the adoption of any new know-how. ‘The every day pull once more in route of the traditional chemistry is perhaps so strong which you possibly can lose focus,’ says Scarborough, Nonetheless he says the group at Syngenta aren’t giving up.

Additional distinctive to this know-how is the mismatch throughout the talents set of many synthetic pure chemists. Lam jokes that a whole lot of them had been seemingly traumatised by bodily electrochemistry as undergraduates. Scarborough has seen associated reservations. ‘After I started [doing electrosynthesis] at Syngenta, I had some people having a look at me like I was crazy to plug this response into the wall,’ he remembers. ‘People had been very nervous in regards to the prepare initially’.

‘Corporations are stuffed with people who’ve been using thermal chemistry and thermal catalysis for a few years, so it takes time to teach people and make them merely eager to take heed to you and take a look at potential benefits,’ says Tessonnnier. In his experience pharma corporations seem most open to differ.

Nonetheless Waldvogel is glad electrosynthesis can have an enormous impact. ‘I’m very assured that it’s not a bubble… merely take into accout, you is perhaps additional oxidising than fluorine gasoline and further decreasing than caesium…. an entire lot of points are potential.’

The final phrase downside is to activate carbon dioxide electrochemically to utilize as a synthetic establishing block, an area Lam is engaged on. Nonetheless he concludes ‘electrosynthesis is not magic’, and it’ll most likely sometimes be oversold. It’s not going to interchange normal chemistry. ‘These are utterly completely different utilized sciences and complementary utilized sciences,’ says Tessonnnier . However it does provide one other methodology to drive a chemical response and one different instrument throughout the industrial chemist’s toolbox.

Rachel Brazil is a science creator based totally in London, UK